Fashion and sustainability are two realms that carry a contradiction in terms. Fashion is a subject which changes quickly – sustainability required permanence. The fashion industry is faced between these two worlds. We combine both worlds with innovation and a promise to our environment.

Maibom

for a sustainable

world.

SUSTAINABLE AND INNOVATIVE FABRICS

ECO FINISH by MAIBOM

- We place huge importance on the spare and sustainable use of water, chemicals and energy.

- The Federal Environmental Foundation promoted the construction of our wastewater treatment plant. The waste water is treated in a membrane technology. The tempered recycling water will be reused in the finishing. The wastewater was reduced by 79%. Now it is avoided in advance. Simple we reduced the wastewater per meter from 7 liter to 1.5 liter! Intressting is an comparison to everyday life: One lavatory flush requires 6 liter wastewater!

- 40% of the electricity which is required in the finishing is generated by a CHP plant (cogeneration) with gas engine. The resulting waste heat is provided for dryers. The water used for cooling is heated to 85°C and will be used for washing processes. The environmental impact is annually reduced by 1.000 tons CO².

- Our quality assurance and the corduroy cutting are operated by 50% of solar energy. Futher energy is covered by Eco-energy of hydropower.

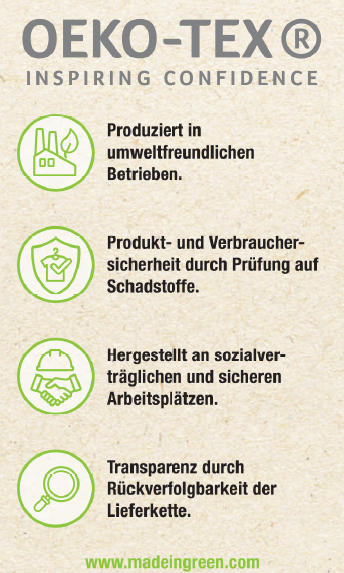

Labeling: MADE IN GREEN by OEKO-TEX®

We are labeled by MADE IN GREEN by OEKO-TEX®. The certification covers all important areas of sustainable production:

- Made with materials tested for harmful substances: A basic requirement for all textiles with the MADE IN GREEN label is that they are safe in terms of human ecology. To ensure this, each item has to pass comprehensive laboratory testing for harmful substances in one of the OEKO-TEX® member institutes.

- Made in enviromentally friendly tested facilities: The use of best available processing technologies that protect the environment and make for an efficient management of resources are key demands for awarding the MADE IN GREEN label. Production facilities are extensively assessed and evaluated by OEKO-TEX® if they meet these criteria.

- Made in safe and socially responsible workplaces: The facilities in which MADE IN GREEN labelled products are manufactured need to be certified by OEKO-TEX® for their fair working conditions. This includes adequate measures to ensure occupational health and safety as well as social aspects such as the exclusion of child labour or discrimination.

Now you can track our supply chain via the QR code on the hangtag or at www.madeingreen.com with our product ID: M1SM41VB9.

If you are not labeled by MADE IN GREEN by OEKO-TEX®, you can advertise our outer fabrics with the following sentence:

The outer fabric has been tested for harmful substances and produced sustainably in accordance with OEKO-TEX® guidelines (MADE IN GREEN by OEKO-TEX® product ID M1SM41VB9, HOHENSTEIN HTTI).